Robotic Sous Chefs Key Takeaways:

- Robotic Sous Chefs leverage sensors, machine vision and AI to do repetitive tasks with consistent results—ideal for high-volume service and those relentless dinner rushes.

- Human Chefs still win on intuition, adaptability and creativity—especially when it comes to signature plates or those last-minute plating flourishes.

- Where robots fall short: Irregular produce, quirky textures, big upfront investment, and the need to alter kitchen routines to fit the machine in.

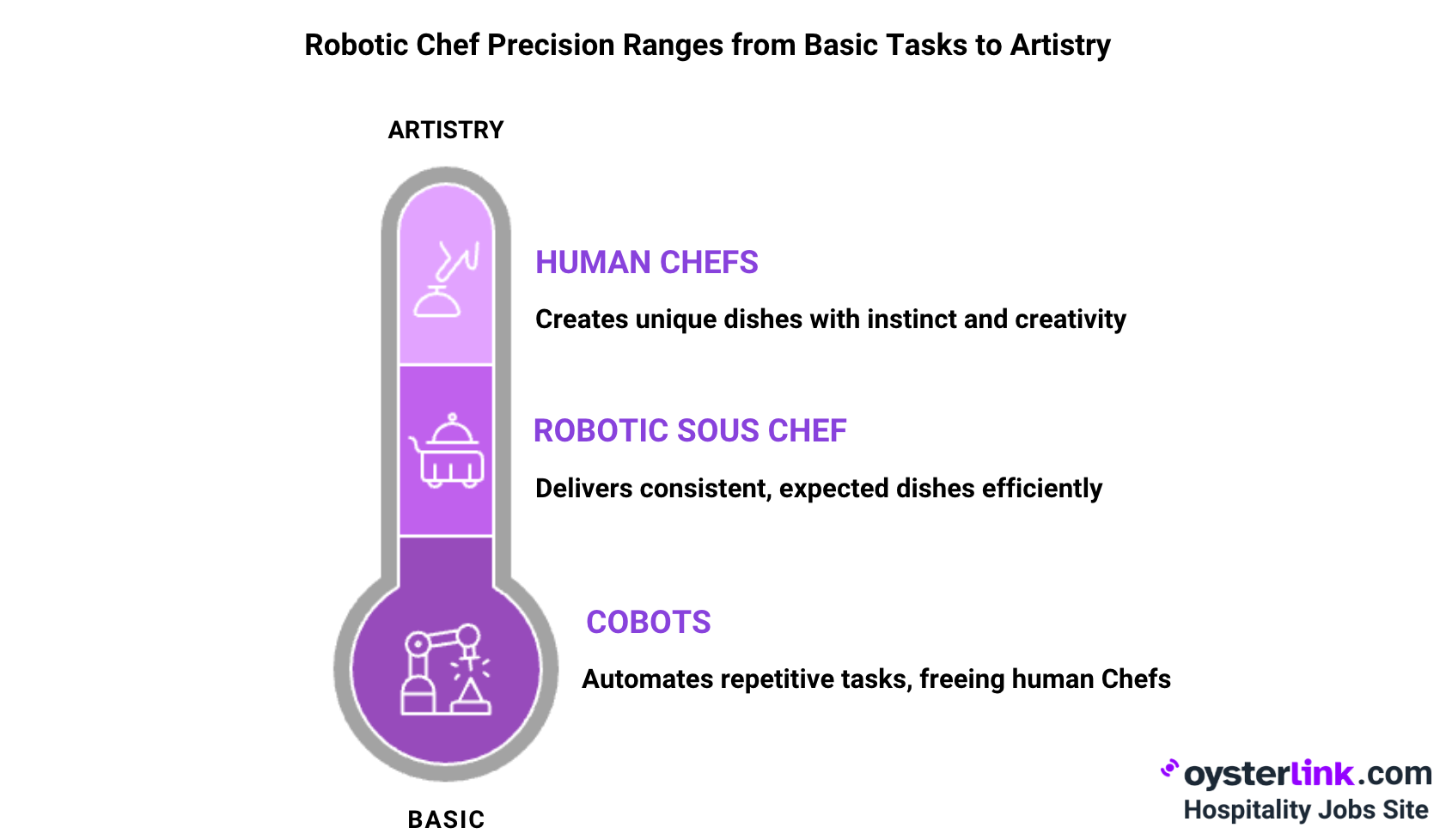

- Cobots (collaborative robots) can work alongside your crew, boosting efficiency and freeing up your pros for the creative stuff.

For forward-thinking restaurateurs eager to boost consistency and efficiency—while never losing that essential spark of creativity—robotics offer new ways to stay ahead in a competitive culinary scene. But are the latest Robotic Sous Chefs really ready for prime time in independent kitchens like yours?

This article compares robotic and human precision, breaks down the tech in straightforward terms, highlights pain points (with context drawn from real kitchen life), and takes a look at what a blend of robots and classic talent could mean for your menu—and your margins.

Evaluating the Precision of Robotic Sous Chefs vs. Human Chefs

.jpg)

As technology continues to reshape the culinary world, robotic sous chefs are becoming more common in kitchens. But how do they measure up to the precision of human Chefs?

While robots excel in consistency and efficiency, human chefs still bring an unmatched level of creativity and adaptability to the table. Let's explore the strengths and limitations of both in achieving culinary perfection.

Defining Precision in the Culinary World

In kitchens, precision isn't just about grams and millimeters: it’s how perfectly you measure, cut, control heat, or time a dish. Seasoned Chefs rely on intuition—trained through years at the line—to push out consistent plates, even with orders stacking up.

If you're considering a career transition in this evolving landscape, check out how to become a Sous Chef for the modern kitchen.

How Robotic Sous Chefs Achieve Precision

Robotic Sous Chefs run on sensors, machine vision and tight programming, serving up extraordinary accuracy for repetitive kitchen jobs. They’re designed to weigh, chop, or portion with minimal difference—perfect for prepping piles of veg or popular menu staples. Plus, they don’t tire out or slip when things get hectic.

Restaurant owners interested in staying ahead should review the latest restaurant industry trends around automation and technology.

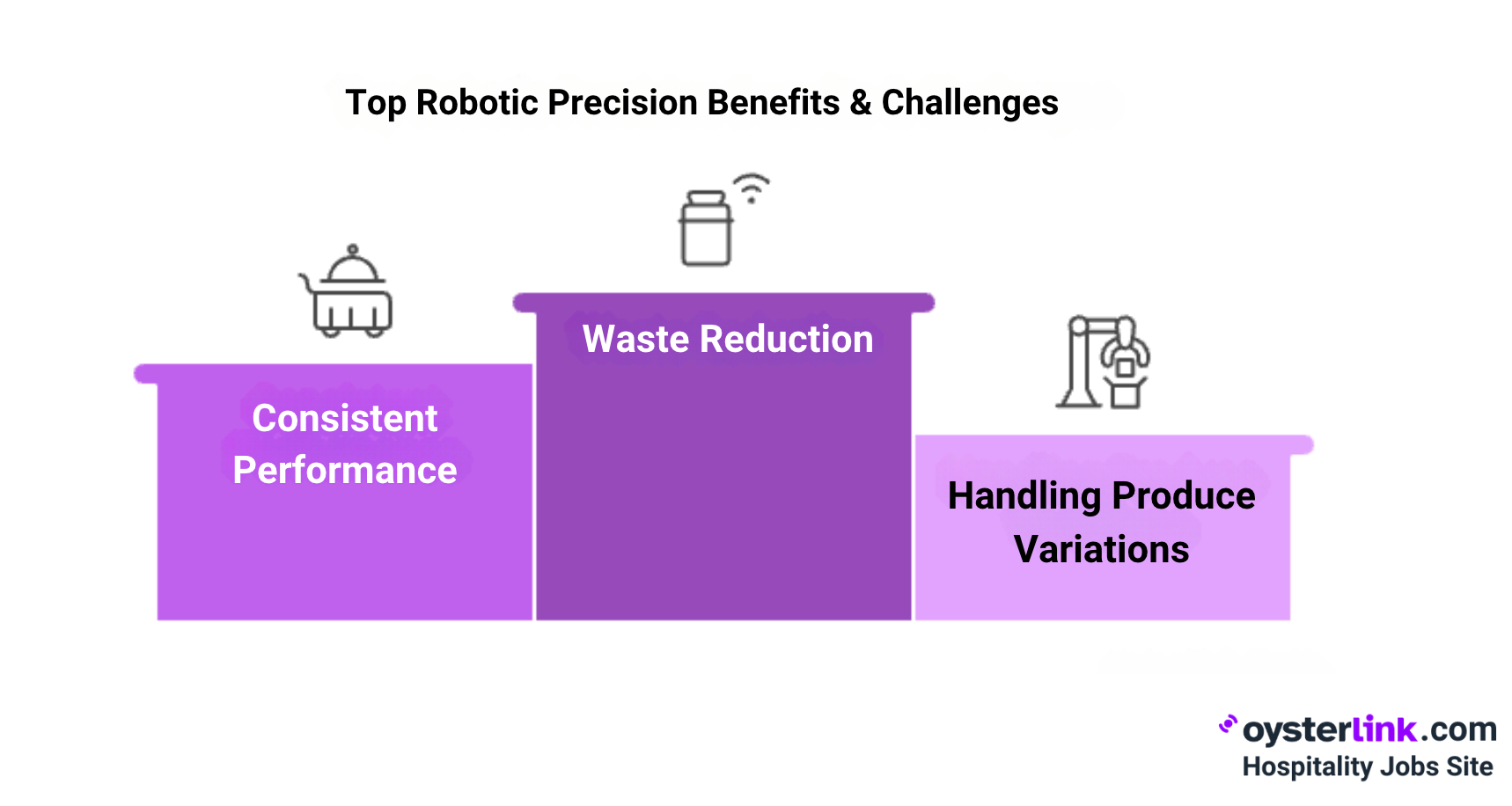

Robotic Precision: Pros & Cons for Small Restaurant Owners

- Pro: Cuts down on waste—no more oversized scoops or uneven slices.

- Pro: Stays laser-focused, even during busy periods or unexpected callouts.

- Con: Has trouble when produce varies (e.g., oddly shaped carrots or super-ripe fruit)—sometimes, someone’s got to step in.

Areas Where Human Precision Excels

Chefs and veteran Line Cooks shine when things go sideways: a bruised tomato, a request for a special order on the fly, or an allergy that needs special handling. Real skill means adapting, improvising and trusting your gut—qualities that set a Chef-driven spot apart from the chains.

For artistic plating or critical last-second saves, humans are still in their own league. If you want to hire talent capable of such adaptability, see expert advice on how to hire top Chefs for your kitchen.

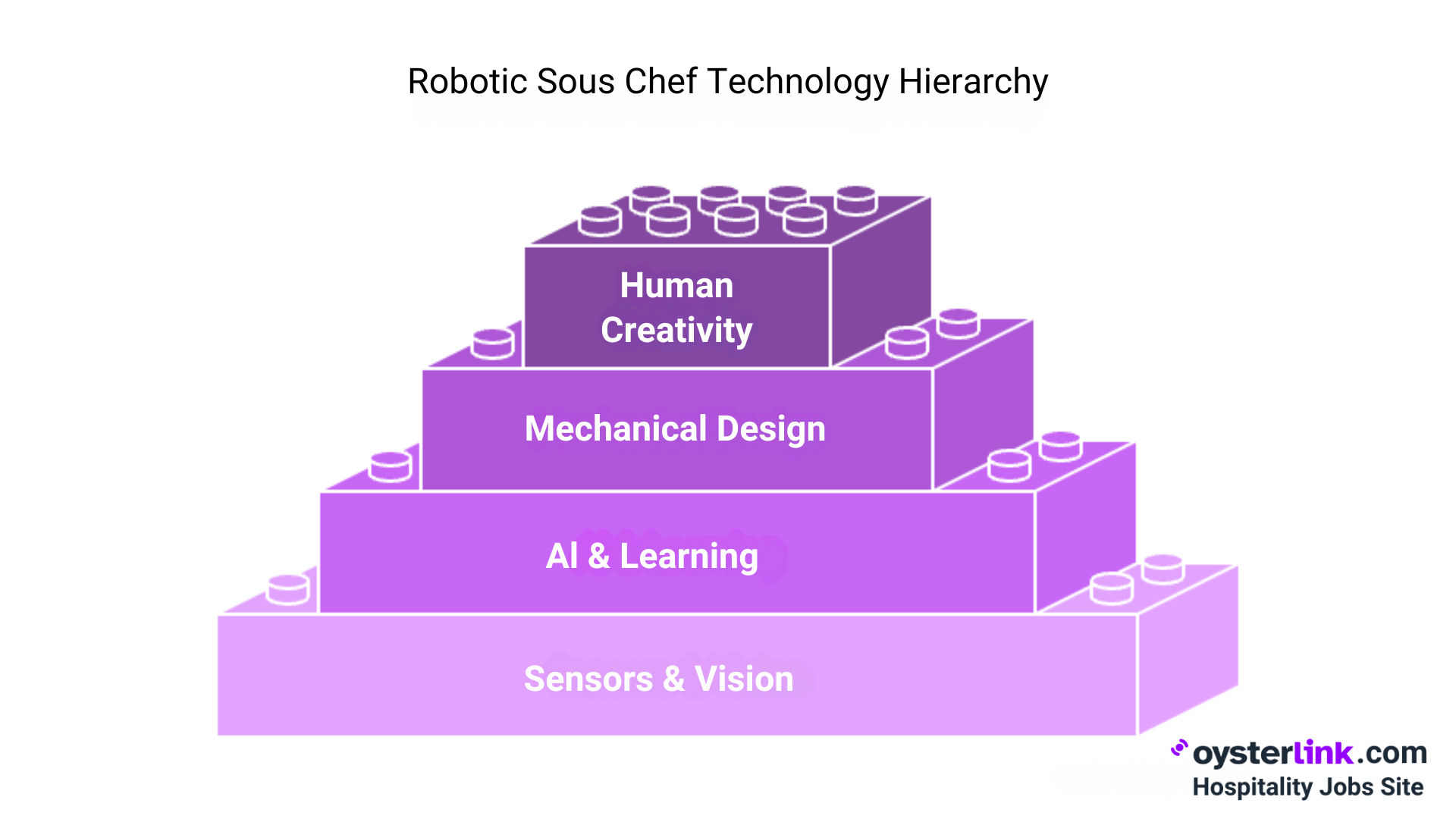

Key Technologies Powering Robotic Sous Chefs

As robotic Sous Chefs become more integrated into modern kitchens, a range of advanced technologies make them more efficient and precise. These innovations, from sensors to artificial intelligence, allow robots to handle repetitive tasks with speed and accuracy.

However, while they excel in certain areas, their limitations become clear when faced with the creativity and adaptability that human Chefs bring to the table. Let’s take a closer look at the key technologies driving this culinary revolution.

Sensors and Machine Vision

Modern robotic Sous Chefs are equipped with an array of advanced sensors and machine vision. These "digital eyes" and "hands" can assess the size, weight and texture of ingredients, allowing robots to perform repetitive tasks like dicing large quantities of carrots with impressive accuracy.

However, when faced with irregular produce—like a ripe, uneven heirloom tomato—these robots may struggle, requiring human intervention to ensure quality.

Artificial Intelligence and Machine Learning

AI and machine learning are what give robotic sous chefs the ability to adapt and improve over time. These technologies enable robots to learn from past experiences, adjusting to slight variations in ingredients and cooking conditions.

While they excel at optimizing repetitive tasks, robots still face challenges when it comes to uncharted territory, such as a new menu or unconventional techniques. These technologies can be powerful tools to support a Sous Chef’s work, but they’re not yet ready to replace the human touch in every aspect of culinary creativity.

Mechanical Design and Dexterity

The mechanical design of robotic Sous Chefs—equipped with flexible grippers and specialized tools—allows them to carry out a wide range of tasks. These robots can perform basic functions with surprising versatility.

However, when it comes to delicate tasks like artistic plating or achieving the perfect sear on a steak, the fine motor skills and creative judgment of a human Chef remain unmatched. The precision and artistry required for these tasks still fall squarely within the Chef’s domain.

Current Limitations of Robotic Sous Chefs

While robotic Sous Chefs bring impressive precision and efficiency to the kitchen, they still face significant challenges that limit their full potential. From their inability to handle unpredictable variables to the high costs of integration and maintenance, these robots aren't quite ready to replace human Chefs entirely.

Let’s dive into the key limitations of robotic Sous Chefs and how these obstacles can impact your kitchen operations.

Lack of Adaptability to Unpredictable Variables

Robots thrive on routine and sameness. When your produce order comes in riper than yesterday or you want to sub in wild local herbs last minute, you’ll need to tweak the robot—or jump in yourself. Quick thinking and a hands-on approach are your kitchen’s real “insurance policy.”

For more on building teams that can thrive alongside automation, explore best practices for restaurant staff hiring.

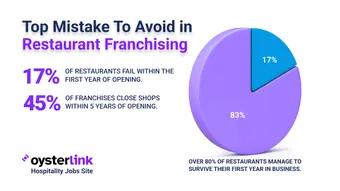

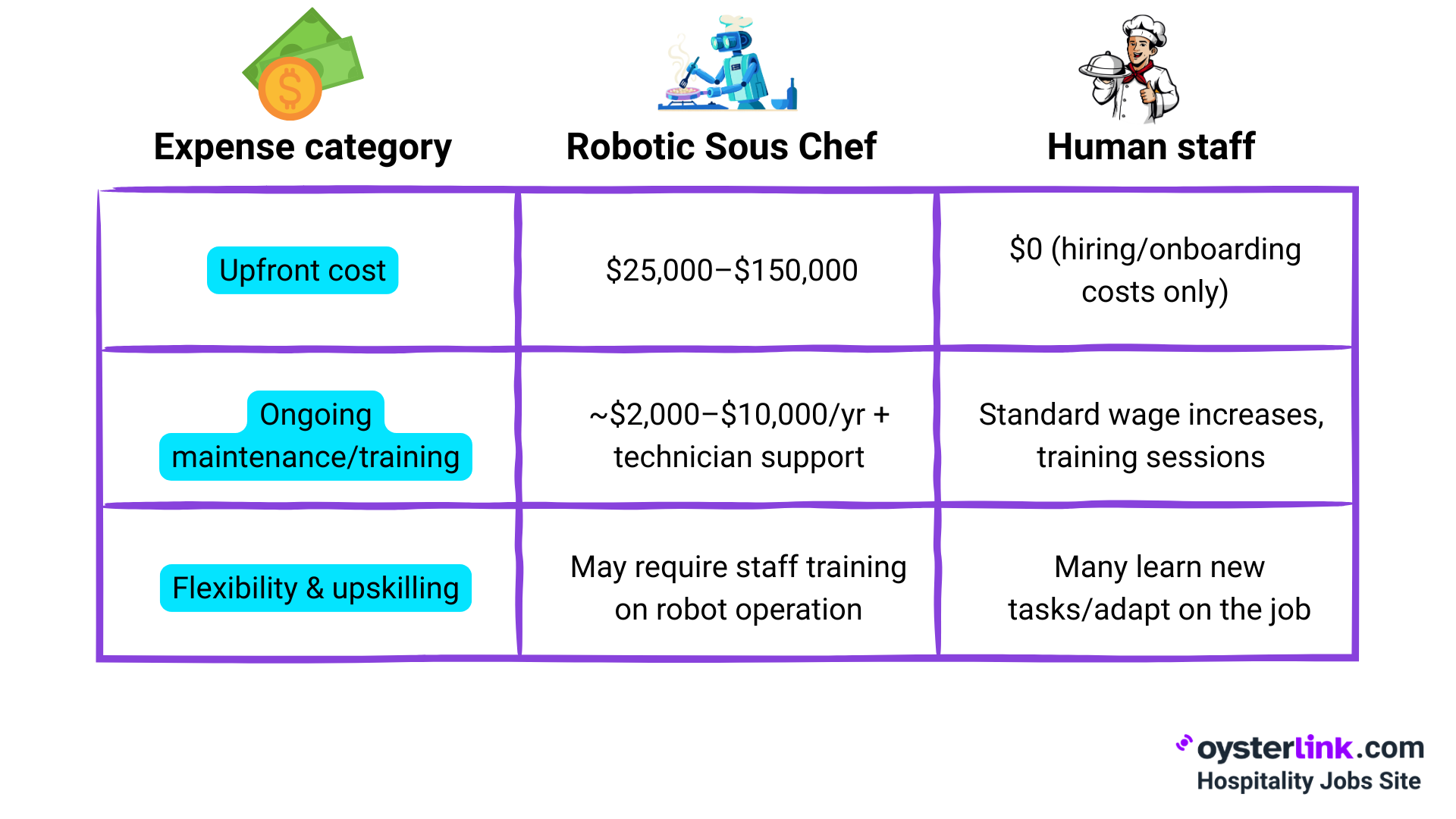

Cost, Maintenance, and Integration Challenges

Getting a Robotic Sous Chef in your kitchen isn’t cheap: you’re looking at a big initial expense, plus installation, training and maybe even remodeling. And while they don’t call out sick, robots do need tech support and can gum up the workflow while things are getting settled.

Quick Considerations:

- Integration curve: It’ll take some trial and error before your kitchen hits its stride. Staff buy-in is essential.

- Staff impact: You’ll get the most from robotics if you train trusted team members to operate them—don’t just swap out people for machines.

Potential Future Improvements in Robotic Precision

As robotics continue to evolve, advancements in precision and adaptability are on the horizon. With better sensors, robots will soon be able to detect subtle changes in texture, doneness and even aromas.

These improvements will bring robotic Chefs closer to mimicking the precision of human Chefs, though replicating the instinct and creativity of a seasoned Chef is still some time away. Let’s explore how these innovations will impact robotic precision in the kitchen and enhance their role alongside human talent.

Enhanced Sensing and Feedback Systems

Advancements in sensor technology are bringing us closer to robots that can detect texture, doneness and even aromas—narrowing the gap between automation and the precision of a seasoned Chef.

However, these machines still fall short of capturing the instinct and creativity that only human Chefs bring to the kitchen. For those famous for crafting one-of-a-kind, made-to-order dishes, the human touch remains indispensable.

Integration with Human Chefs

“Cobots,” or collaborative robots, shine when they’re paired with kitchen talent—not used as a replacement. They breeze through bulk work (rolling dough, slicing, portioning sides), freeing up your pros for cooking and troubleshooting. In other words, it’s teamwork, not takeover.

If you're interested in managing these dynamics, review proven top kitchen staff skills every modern operation should cultivate.

Implications for the Culinary Industry

As robotics and automation continue to advance, the culinary industry faces significant transformations. While these technologies promise efficiency, consistency and cost-saving potential, they also bring challenges and require a shift in how kitchens operate.

From enhancing food quality to reshaping workforce dynamics, the impact of robotic Sous Chefs and automation in professional kitchens will be far-reaching. Let’s explore the key implications for both kitchen operations and the broader dining experience.

Impact on Professional Kitchens

Adopting kitchen robotics can seriously bump up output and consistency. There is a cost—the transition comes with bumps in the road and means culinary staff need to add tech know-how to their skills list. In smaller restaurants, part-robot, part-human teams are the most realistic approach, letting your creativity shine.

To dive deeper, see the latest tips in restaurant management for tech-driven kitchens.

Consumer Experience and Food Quality

Guests who stick to their favorites appreciate consistency; robots help you deliver exactly what they expect each time. But the folks who come for surprise specials or chef-tweaked favorites? They’ll still look for that human artistry—a detail even the best robot can’t yet program in.

Ethical and Economic Considerations

The role of robotics in kitchens isn’t just about cutting labor costs—it’s about reshaping the future of work in the culinary world. Robots can ease physical strain, improve food safety and increase consistency, but their integration should enhance, not replace, human talent.

Many progressive restaurant owners are turning to automation as an opportunity to upskill their teams, adding value to staff roles rather than eliminating them.This balance of human and machine can also be a powerful marketing tool.

Customers who appreciate both tradition and innovation will be drawn to your kitchen’s ability to blend cutting-edge technology with timeless culinary expertise. By highlighting this collaboration, you create a unique dining experience that appeals to the modern consumer.

Making the Decision: Is Robotics Right for Your Kitchen?

Thinking about diving in? Talk to other owners who've road-tested robotics and loop your staff in from the start. Try pilots during slower shifts so you can see real time and cost gains—plus, you’ll build trust with your team in the process. Both regulars and new staff will appreciate the balance of new tech with the familiar, friendly vibe they know you for.

If you go for it? Have some fun—lots of kitchens name their robot helpers. (“Ladlebot” and “RoboPrep” are out there... bet you can top that.) Make innovation your own, and your team and guests will follow.